Gas Cylinder Tracking in Michigan: Compliance & Efficiency

How smarter tracking keeps businesses compliant and operations running smoothly

If your business uses industrial, specialty, or medical gases, managing cylinders is more than just logistics—it’s compliance, safety, and efficiency rolled into one. Across the state, companies are realizing that gas cylinder tracking in Michigan isn’t optional anymore; it’s essential to staying out of trouble and ahead of the curve. With rising regulatory scrutiny and the high cost of misplaced cylinders, investing in the right tracking system can help businesses avoid fines, save time, and streamline operations.

Think of cylinder tracking as insurance for your workflow. It protects your team from last-minute shortages, keeps regulators satisfied with up-to-date records, and prevents costly mistakes that chip away at your bottom line. Whether you’re in healthcare relying on oxygen cylinders, a brewery managing CO2 deliveries, or a manufacturer juggling dozens of welding gases, having a structured tracking process ensures accountability. When paired with bulk gas delivery Michigan services, tracking systems also provide real-time visibility, helping you plan smarter, reduce waste, and stay prepared for unexpected demand spikes. In today’s competitive market, efficiency is survival—and tracking is your edge.

The Hidden Cost of Cylinder Mismanagement

Every gas cylinder has value, not only for the gas it contains but for the container itself. Failing to track cylinders properly can lead to:

- Regulatory Fines: Federal and state agencies require accurate record-keeping of compressed gases. Missing or mislabeled cylinders can trigger costly penalties.

- Lost Assets: A misplaced high-pressure cylinder can cost hundreds of dollars to replace, cutting into profits.

- Operational Delays: When the right gas isn’t available because cylinders weren’t returned or refilled on schedule, production lines, restaurants, or hospitals face downtime.

Michigan businesses that rely on bulk gas delivery Michigan services are especially vulnerable. With larger volumes moving through multiple departments or locations, tracking errors compound quickly. A single missing shipment can snowball into delays that frustrate customers and damage reputation. Over time, those “little losses” become major expenses. What’s worse, many companies don’t realize the extent of the problem until they audit their cylinder inventory and discover tens of thousands of dollars tied up in unreturned containers. By proactively addressing tracking, businesses can transform what feels like a hidden cost into measurable savings and stronger compliance.

Compliance Made Simple

Cylinder tracking is not just about avoiding headaches—it’s about staying compliant. OSHA, DOT, and state-specific rules mandate strict handling and documentation.

Key compliance factors include:

- Cylinder identification and labeling.

- Documenting fill and return dates.

- Maintaining logs for safety inspections.

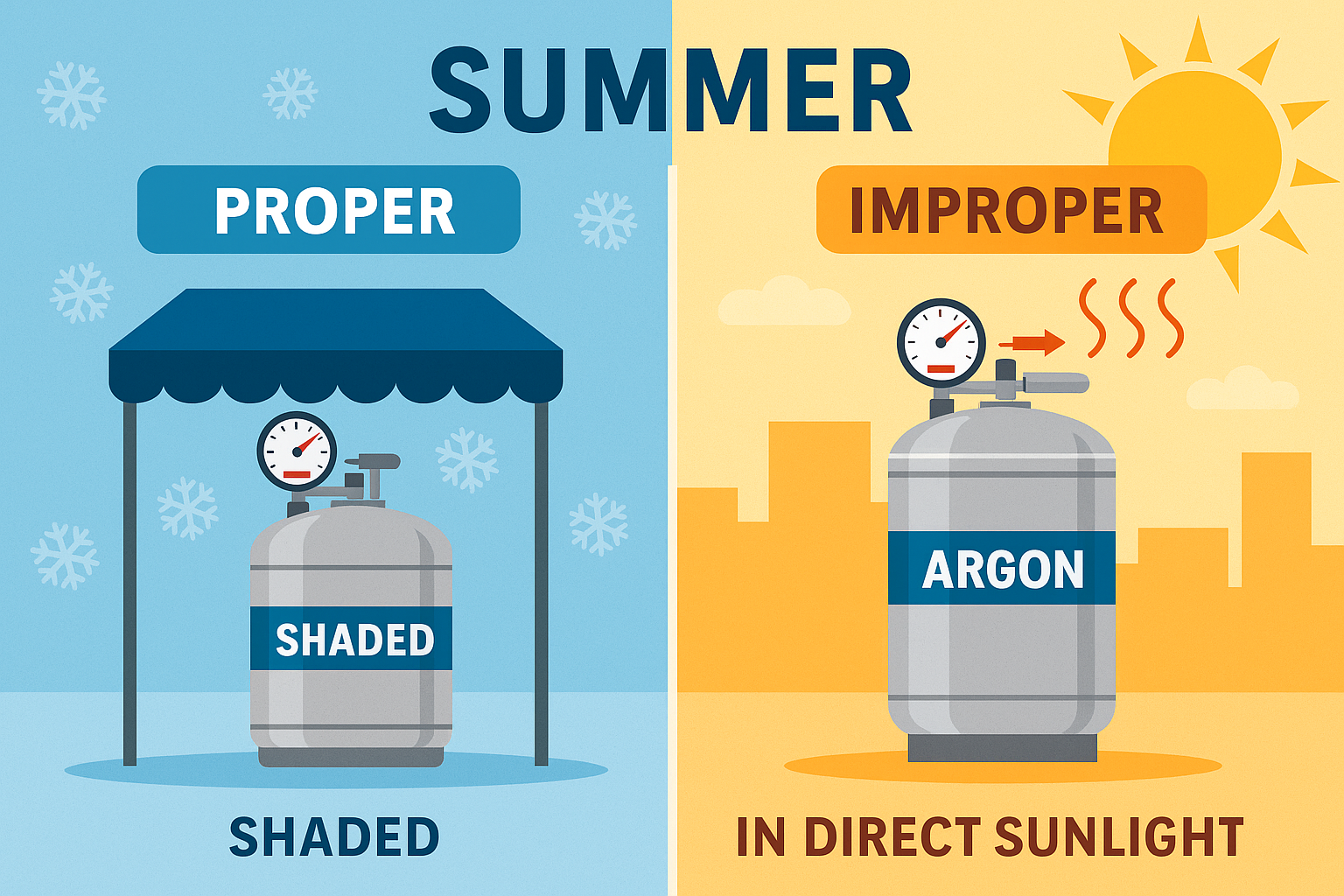

- Ensuring proper storage conditions.

A robust cylinder tracking system provides automatic updates, digital logs, and reporting features. This means businesses can quickly provide compliance records during inspections without wasting hours digging through paperwork.

Beyond passing inspections, compliance builds trust. Healthcare organizations, for example, need proof that oxygen and nitrous oxide cylinders are monitored at all times. Manufacturers must show regulators that their welding gases are stored properly. Even restaurants using CO2 must meet safety codes. A system that simplifies compliance reduces human error and creates a digital trail that auditors appreciate. For businesses using bulk gas delivery Michigan services, compliance tracking also ensures cylinders are rotated and tested on time, protecting both employees and customers while safeguarding long-term profitability.

How Tracking Systems Work

Modern gas cylinder tracking solutions combine barcodes, RFID tags, or QR codes with software that records every movement. From the supplier’s warehouse to your delivery dock and back, each cylinder is scanned at every stage.

- Barcode & QR Code Tracking: Affordable and simple to use with mobile devices.

- RFID Systems: Automated scanning reduces human error and provides real-time inventory.

- Cloud-Based Dashboards: Accessible from desktops or mobile apps, so managers always know where cylinders are located.

By implementing these tools, businesses across Michigan are reducing losses, cutting administrative costs, and freeing up employees to focus on operations instead of paperwork.

The best systems also integrate with purchasing and delivery schedules, ensuring that businesses never run short of critical gases. Imagine a brewery automatically receiving alerts when CO2 levels drop, or a hospital seeing oxygen cylinder status updated instantly after delivery. That level of transparency makes planning easier, improves communication with suppliers, and minimizes waste. When paired with bulk gas delivery Michigan providers who understand local industries, these tracking systems don’t just monitor assets—they actively improve business efficiency.

Why Bulk Gas Users Need Tracking the Most

Companies that rely on bulk gas delivery Michigan services often juggle hundreds—or even thousands—of cylinders at a time. Industries like healthcare, manufacturing, food and beverage, and research can’t afford missteps.

- Healthcare Facilities: Hospitals need precise accountability for oxygen, nitrous oxide, and other life-saving gases.

- Food & Beverage: Breweries and restaurants rely on CO2 delivery to keep beverages perfectly carbonated. Losing track of cylinders creates service disruptions.

- Manufacturing: Welding operations depend on argon, oxygen, and acetylene. Mismanaged cylinders equal production downtime.

- Research Labs: Sensitive experiments rely on specialized gases that must be delivered and tracked with precision.

For these industries, advanced tracking is less of an option and more of a requirement. Tracking systems allow managers to see which cylinders are empty, which are overdue for inspection, and which are sitting idle. That visibility translates into smarter purchasing and scheduling, reducing unnecessary orders and ensuring gases are always available where they’re needed most. In competitive sectors, where every second of downtime costs money, proper tracking isn’t just about efficiency—it’s about survival.

Saving Time and Money

Tracking gas cylinders doesn’t just keep you compliant—it saves money. Businesses that adopt tracking systems often see:

- Lower Replacement Costs: Fewer lost or unreturned cylinders.

- Streamlined Delivery Schedules: Accurate forecasts for refills and exchanges.

- Reduced Labor Costs: Less time spent manually logging cylinder movement.

- Improved Safety: Quick detection of overdue inspections or expiring cylinders.

This efficiency pays dividends across every department, from accounting to operations. With precise tracking, finance teams can reconcile cylinder deposits faster, operations staff can optimize usage, and managers gain confidence in budgeting for future deliveries. For businesses using bulk gas delivery Michigan, predictive analytics built into tracking systems also help forecast seasonal demand spikes—whether that’s oxygen during flu season or CO2 during peak restaurant months. Over time, the savings compound into significant long-term value, turning cylinder management from a headache into a competitive advantage.

Metro Welding Supply: Tracking Made Easy

Metro Welding Supply understands the challenges Michigan businesses face. That’s why we provide gas cylinder management solutions designed to simplify compliance and streamline operations. With delivery routes covering Detroit, Ann Arbor, Toledo, and beyond, we don’t just drop off cylinders—we help our customers manage them with confidence.

Whether you’re a hospital administrator trying to balance patient care with regulations, or a brewery owner focused on keeping taps flowing, Metro Welding Supply offers the tools and expertise you need. Pairing gas cylinder tracking Michigan with reliable bulk gas delivery Michigan services ensures your operations are both safe and efficient.

What sets us apart is our local knowledge and customer-first approach. We offer tailored delivery schedules, emergency response support, and advanced tracking tools that integrate seamlessly into your existing workflow. Our decades of experience mean we anticipate seasonal spikes, help you stay compliant, and reduce downtime before it happens. By choosing Metro Welding, you’re choosing a partner who treats your business like their own—delivering not just gases, but peace of mind.

Final Thoughts

Gas cylinders are the lifeblood of countless Michigan businesses, but without proper tracking, they can quickly become a liability. Regulatory fines, lost assets, and operational delays are all preventable with the right system in place. By investing in tracking, businesses save time, money, and stress while ensuring safety and compliance.

For companies across Southeast Michigan and Northern Ohio, Metro Welding Supply delivers more than just gas—we deliver peace of mind. Our team is ready to help you modernize your operations, avoid costly mistakes, and keep your business moving forward.

The message is clear: ignoring cylinder tracking costs more than implementing it. From small restaurants with CO2 tanks to hospitals managing critical oxygen supplies, every business benefits from accurate accountability. When combined with bulk gas delivery Michigan, tracking creates a complete solution that safeguards your reputation, protects your people, and maximizes efficiency. At Metro Welding Supply, we’re not just your supplier—we’re your partner in compliance, safety, and success.

Ready to work with Metro Welding Supply Corp.?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 313-834-1660