Laser Cutting Gases in Ann Arbor: Optimizing Performance and Precision

Optimizing Laser Cutting with the Right Industrial Gases

Laser cutting isn’t just about the laser beam—it’s about the environment surrounding that beam. The assist or shielding gas used during cutting plays a critical role in:

- Cut quality

- Speed

- Thermal distortion

- Material edge finish

- Cost per part

The right gas ensures cleaner cuts, fewer defects, and longer machine life. The wrong gas—or an inconsistent supply—can result in burrs, discoloration, oxidation, and even failed cuts, especially with tight tolerances.

Even the most advanced laser system can underperform without the correct gas type, purity level, and flow control. Gases like nitrogen and oxygen require precision regulation and filtration to avoid micro-contaminants that disrupt the beam’s stability. The gas you choose must also match your metal type, thickness, and desired finish. For example, mild steel cut at 1/4” thickness may benefit from oxygen for speed, while stainless steel demands nitrogen for a clean, oxidation-free edge.

High-performance gases allow operators to push their systems to the limits—maximizing speed without compromising integrity. For Ann Arbor’s precision industries, including aerospace, automotive prototyping, and university R&D, this translates to less rework, shorter lead times, and more profitable production.

Types of Laser Cutting Gases and Their Applications

1. Oxygen (O₂)

- Commonly used for

mild steel

- Enables

oxidation reactions that increase cutting speed

- Can cause slight edge discoloration

- Requires

precise flow control for clean cuts

2. Nitrogen (N₂)

- Ideal for

stainless steel, aluminum, and galvanized metals

- Produces

oxidation-free edges

- Preferred for

aesthetic parts with no post-processing

- Requires high-purity supply and adequate pressure

3. Argon (Ar)

- Used in

non-ferrous materials, titanium, and heat-sensitive metals

- Inert gas that protects against oxidation and heat distortion

- More expensive, but worth it for

high-end precision jobs

4. CO₂ Gas

- Sometimes used in

CO₂ lasers as a lasing medium

- Requires careful moisture and impurity control

- Supports longer beam life and cleaner energy transfer

Different laser processes demand different gas mixes, and those gases must be delivered at the right purity, pressure, and flow rate. That’s where a local Ann Arbor industrial gases supplier comes in.

Why Choose a Local Laser Gas Supplier in Ann Arbor?

✅ Faster Turnaround and Delivery

You can’t afford downtime waiting for your next shipment from out of state. With local hubs in Ann Arbor and Southeast Michigan, Metro Welding Supply offers same-day and next-day delivery on high-purity laser gases.

✅ High Purity Guaranteed

Contaminated gas equals compromised quality. We offer laser-grade purity levels that meet or exceed ISO and AWS standards—so you get clean, repeatable results with every cut.

✅ Custom Gas Blends and Packaged Systems

Need nitrogen with a specific dew point? Want a blend that optimizes cutting aluminum while minimizing dross? We can provide:

- Pre-mixed cylinders

- Microbulk and bulk supply options

- Packaged gas delivery for on-demand usage

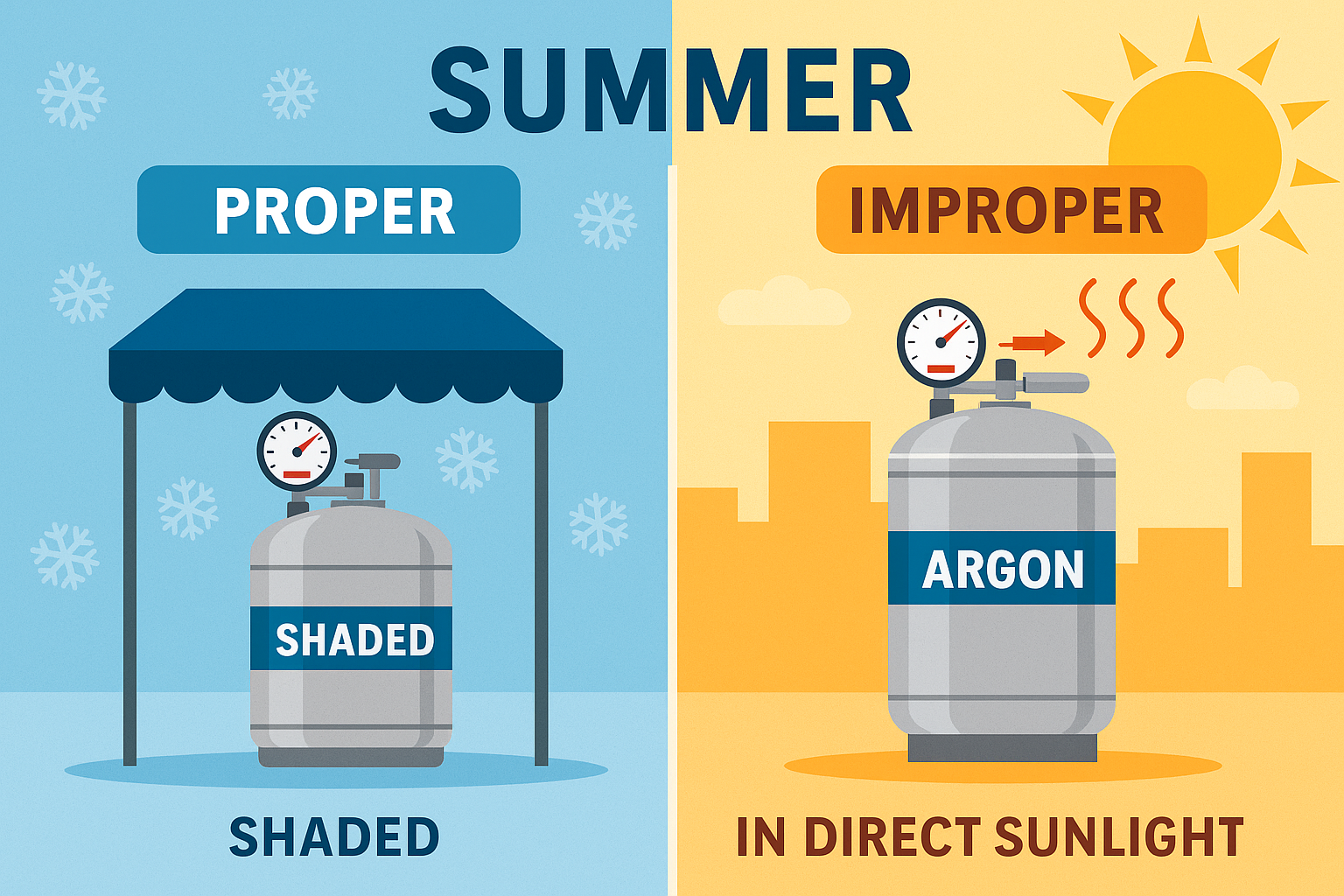

✅ Pressure Monitoring and Regulator Guidance

Improper tank pressure leads to inconsistency. Our specialists help you set up and maintain:

- Gas manifolds

- Flow regulators

- Inline filters

- Backup supply systems

✅ Local Support from People Who Understand Your Work

Metro Welding Supply has supported Southeast Michigan’s fabrication, automotive, and manufacturing industries since 1937. We don’t just drop off tanks—we partner with your shop to keep your lines cutting clean all summer long.

How Ann Arbor Manufacturers Benefit From Local Laser Gas Supply

Laser cutting is booming in Ann Arbor, thanks to:

- Growth in biotech, aerospace, and defense

- Expansion of university-based R&D

- Custom fabrication needs for tech startups and labs

By working with a trusted local gas supplier, shops gain:

- Shorter lead times

- Cost-efficient delivery

- No minimum order limitations

- Emergency gas replacement options

- Expertise tailored to Michigan’s manufacturing climate

What makes local supply even more valuable is the ability to build a relationship with a responsive team who understands your daily challenges and long-term goals. Whether you're scaling production or troubleshooting inconsistent cuts, a nearby supplier like Metro Welding Supply can provide on-site support, faster issue resolution, and flexible delivery adjustments that national suppliers simply can’t match. In an industry where uptime equals revenue, local expertise isn’t a convenience—it’s a competitive advantage.

Troubleshooting Common Laser Gas Problems

If you're facing these issues, your gas might be the culprit:

| Problem | Possible Cause | Gas-Related Solution |

|---|---|---|

| Burned or oxidized edges | Too much oxygen or moisture | Switch to nitrogen or dry argon |

| Inconsistent cutting quality | Pressure drop or gas contamination | Upgrade regulators or tank supply |

| Machine downtime | Tank replacement delays | Use telemetry-monitored microbulk |

| Burrs or slag on edges | Incorrect gas type or flow rate | Adjust PSI or switch to nitrogen |

Why Purity and Flow Control Are Crucial

Even slight contamination in your gas lines can alter the beam’s intensity, disrupt thermal dynamics, and increase post-processing time. Metro Welding Supply offers 99.999% purity gases, along with:

- Cylinder batch certification

- Inline filtration

- Moisture and hydrocarbon detection

- Telemetry-based tank monitoring

Consistency in flow rate is equally important. If your gas delivery fluctuates—even momentarily—it can cause inconsistent kerf width, rough edges, or incomplete cuts, especially on sensitive materials like aluminum or stainless steel. Maintaining stable flow not only protects your laser head and optics but also ensures predictable, repeatable results across every shift. That’s why we also offer precision flow meters, pressure regulators, and gas management systems designed to safeguard your output and reduce costly rework.

Final Thoughts: Precision Starts with Gas

Laser cutting success begins with gas quality. Whether you’re running prototype batches, mass-producing components, or fabricating one-off custom designs, your gas system is at the heart of your workflow.

By partnering with a local Ann Arbor industrial gases expert like Metro Welding Supply, you're gaining:

- Better control

- Faster service

- Lower costs

- More uptime

- Cleaner, more precise cuts

And with the ever-increasing demand for tighter tolerances, faster production cycles, and material versatility, having a reliable gas partner gives your operation the edge it needs to stay competitive. From fabrication shops and contract manufacturers to university research facilities and OEM suppliers, more Ann Arbor businesses are discovering how the right gases can optimize not just output—but overall business performance.

At Metro Welding Supply, we don’t just deliver cylinders—we deliver confidence, consistency, and competitive advantage. Backed by decades of industry expertise, local delivery routes, and certified high-purity gases, we’re here to support your precision from the first cut to the final product. If you’re ready to scale your laser cutting operation with better performance and fewer variables, we’re the local partner who’s ready to help you do it.

📞 Ready to Upgrade Your Laser Cutting Gases?

Request your customized quote today

Ready to work with Metro Welding Supply Corp.?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 313-834-1660