Why Microbulk Gas Systems in Ann Arbor Are the Future of Gas Supply for Research Labs

Why Cutting-Edge Labs in Ann Arbor Are Ditching Cylinders for Scalable Gas Solutions

Research labs in Ann Arbor—from university environments to private R&D facilities—demand precision, reliability, and efficiency. Whether they’re developing new medical technologies, performing chemical analysis, or pushing the boundaries of material science, one thing is constant: they all rely on a consistent and pure supply of industrial gases.

As research evolves and demands increase, traditional cylinder delivery models are becoming outdated. Enter microbulk gas systems in Ann Arbor—a smarter, safer, and more scalable solution that’s quickly becoming the go-to choice for forward-thinking labs. In this article, we’ll explore why microbulk is the future of gas supply, how it works, and why choosing a trusted industrial gas supplier in Southeast Michigan makes all the difference.

The Evolution of Gas Supply in Research Labs

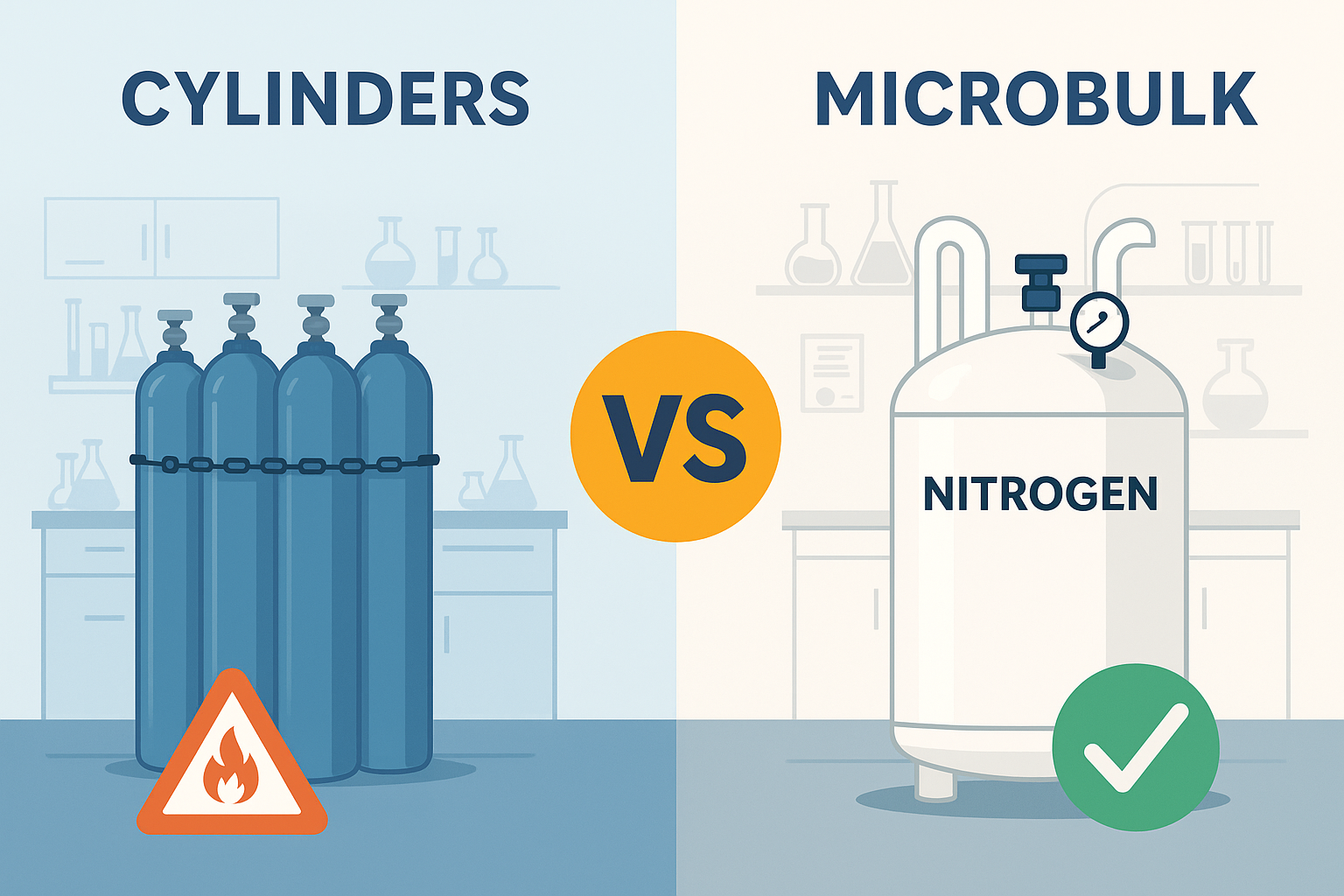

Traditionally, research labs have depended on high-pressure cylinders to store and deliver gases like nitrogen, argon, carbon dioxide, and oxygen. While functional, this model presents several challenges:

- Frequent cylinder changeouts disrupt workflow

- Pressure inconsistencies can affect experimental results

- Storage space constraints limit productivity

- Manual handling increases safety risks

With the growing complexity of modern research, these limitations can cost time, money, and even data integrity. That’s why labs across Ann Arbor—especially those operating at scale—are shifting toward microbulk systems as a modern alternative.

What Are Microbulk Gas Systems?

Microbulk gas systems are on-site refillable tanks that hold liquefied gases in volumes typically ranging from 230 to 1,500 liters. These tanks are installed directly at your facility and automatically refilled by your supplier on a schedule—or via telemetry when levels get low.

Unlike traditional cylinders, which require manual handling and frequent replacements, microbulk systems offer:

- Continuous gas flow

- Greater gas storage efficiency

- Improved safety and ergonomics

- Data tracking via telemetry

Think of it as your own gas station on-site, specifically designed to meet the high-purity, high-volume needs of a research lab environment.

Why Research Labs in Ann Arbor Are Embracing Microbulk

Ann Arbor is home to world-class institutions like the University of Michigan, as well as numerous biotech startups, pharma companies, and contract research organizations (CROs). These organizations rely on accuracy and uptime, making the switch to microbulk an easy decision.

Here’s why more labs are making the move:

1. Uninterrupted Gas Supply for Critical Processes

Microbulk tanks eliminate the need for cylinder swaps, providing a continuous and uninterrupted flow of gas. This is especially important in long-duration experiments, clinical sample preservation, and high-throughput environments.

2. Enhanced Safety

Manual cylinder handling carries risks: back injuries, leaks, tip hazards, and compressed gas accidents. Microbulk systems are stationary, sealed, and tamper-resistant, dramatically improving lab safety protocols.

3. Improved Space Efficiency

Cylinders are bulky, and they require cages, strapping, and dedicated floor space. Microbulk tanks are installed in compact footprints—often outside the building—freeing up lab space for more productive uses.

4. Cost Savings Over Time

While the upfront setup may be higher, microbulk delivery reduces operational costs in the long run. Fewer deliveries, lower labor demands, and reduced loss from gas waste or partial cylinder returns lead to substantial savings.

Smart Delivery with Southeast Michigan's Trusted Gas Supplier

Switching to microbulk is only half the equation—the other half is finding a reliable partner. As a long-standing industrial gas supplier in Southeast Michigan, Metro Welding Supply provides tailored microbulk solutions with white-glove service across the Ann Arbor region and beyond.

Here’s what sets us apart:

✅ Custom-Tailored Solutions

We perform on-site evaluations to assess your lab’s gas usage, future demand, and safety compliance needs. From there, we design a microbulk system that’s built to scale with you.

✅ Compliance-First Installations

Every installation is completed with full regard to NFPA, OSHA, and MIOSHA compliance standards. Our technicians ensure your setup meets or exceeds state and federal requirements.

✅ Scheduled or On-Demand Refills

We offer both routine and just-in-time refill services. Whether you need a weekly top-off or support during a spike in usage, we deliver.

Real-World Applications of Microbulk in Research Environments

🔬 Life Sciences Labs

Cryopreservation of cell cultures, tissue samples, and reagents often depends on liquid nitrogen. Microbulk ensures your storage stays at -196°C without fluctuation or disruption.

🧪 Analytical Chemistry

Gas chromatography and mass spectrometry demand high-purity gases like argon and helium. Microbulk eliminates the contamination risks associated with cylinder swaps.

🧫 Pharmaceutical Manufacturing

From pilot batches to GMP production, consistent gas flow is essential for sterile conditions, cleanroom pressurization, and safety. Microbulk gives your team one less thing to worry about.

🧬 University Research Labs

With budgets always under scrutiny, microbulk allows campus labs to consolidate gas sourcing, reduce waste, and minimize admin headaches tied to cylinder tracking and replacement.

How to Know If Microbulk Is Right for You

If you're currently using more than 10 cylinders of the same gas per month, or if your lab experiences downtime during cylinder changeouts, microbulk could be the game-changing solution you need.

Use this quick checklist:

✔️ Do you use nitrogen, CO₂, argon, or oxygen regularly?

✔️ Do you have limited space for cylinder storage?

✔️ Do you operate 24/7 or run long-duration experiments?

✔️ Are you looking to reduce safety incidents and labor costs?

If you answered yes to two or more, it’s time to request a microbulk consultation.

Our Footprint in Ann Arbor and Southeast Michigan

Metro Welding Supply proudly serves:

- University labs

- Biotech incubators

- Healthcare research facilities

- Battery and materials testing labs

- Advanced manufacturing R&D teams

With locations in Detroit and Ypsilanti, we are strategically positioned to serve clients throughout Washtenaw County, Wayne County, Oakland County, and the greater Southeast Michigan region. Our service fleet is local, responsive, and built for flexible deliveries—even in the unpredictable Michigan weather.

Future-Proofing Your Lab’s Gas Supply

Science doesn’t wait—and your gas supply shouldn’t hold you back. Microbulk gas systems in Ann Arbor are more than a trend—they’re the new standard. Labs that adopt this technology now are future-proofing their operations against rising costs, stricter compliance measures, and growing demand.

With research advancing faster than ever and Michigan positioning itself as a biotech and advanced manufacturing hub, now is the time to invest in scalable, secure infrastructure.

Final Thoughts: Small Tanks. Big Impact.

At a glance, switching from cylinders to microbulk might seem like a minor change. But the impact is huge—safer labs, cleaner data, less downtime, and better cost control.

At Metro Welding Supply, we don’t just drop off tanks—we deliver custom-engineered gas solutions designed to help your lab run smarter, cleaner, and more efficiently. Our team is standing by to help research labs across Ann Arbor and Southeast Michigan make the switch and thrive.

📞 Ready to Upgrade Your Lab’s Gas Supply?

Contact us today for a free on-site assessment or to learn more about microbulk gas systems in Ann Arbor:

📍 Serving Southeast Michigan from our Detroit and Ypsilanti locations

Ready to work with Metro Welding Supply Corp.?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 313-834-1660