Microbulk Gases: Benefits, Applications, and Storage Solutions

Introduction to Microbulk Gases

In industries where gases play a crucial role, finding the right balance between efficiency and safety is key. Microbulk gases offer an innovative solution, bridging the gap between traditional high-pressure cylinders and large bulk gas storage. But what exactly are microbulk gases, and how do they benefit various sectors? This guide will explore the concept of microbulk gases, their advantages, applications, and best practices for storage and handling.

What Are Microbulk Gases?

Microbulk gases refer to industrial gases delivered and stored in a unique, on-site system that lies between the use of high-pressure cylinders and large bulk storage tanks. This system allows businesses to have a consistent supply of gases like oxygen, nitrogen, argon, and carbon dioxide, without the hassle of frequent cylinder changes or the need for large storage tanks.

How Do Microbulk Gas Systems Work?

A microbulk system involves a storage tank installed at the customer's site, which is regularly refilled by a supplier. The system typically includes a cryogenic liquid storage tank, a vaporizer, and a control panel to monitor gas levels and pressure. This setup ensures a continuous supply of gas with minimal manual intervention.

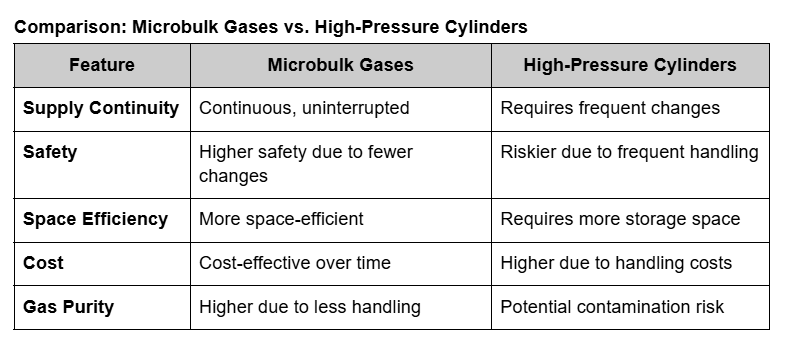

Benefits of Using Microbulk Gases

- Continuous Supply: No need to change cylinders frequently, reducing downtime.

- Cost Efficiency: Lower costs compared to high-pressure cylinders due to reduced labor and handling.

- Enhanced Safety: Fewer cylinder changes mean reduced risk of handling-related accidents.

- Space Efficiency: Microbulk tanks take up less space compared to traditional bulk tanks.

- Better Gas Quality: Reduced handling and contamination risks result in higher purity gases.

Applications of Microbulk Gases

Microbulk gases are used across a wide range of industries, each with specific needs:

- Healthcare

- Hospitals use microbulk systems for medical gases like oxygen and nitrogen, ensuring a steady and reliable supply for patient care.

- Manufacturing

- Industries such as metal fabrication and chemical processing rely on microbulk gases for welding, cutting, and other processes.

- Food and Beverage

- In the food and beverage industry, microbulk systems provide CO2 and nitrogen for carbonation, packaging, and preservation.

- Laboratories

- Research labs use microbulk systems for gases required in various experiments, ensuring consistency and purity.

- Pharmaceuticals

- Critical for maintaining controlled environments and sterilization processes in pharmaceutical manufacturing.

Types of Gases Stored in Microbulk Systems

The most common gases stored in microbulk systems include:

- Oxygen: Used in healthcare, metal processing, and combustion processes.

- Nitrogen: Essential for food preservation, chemical manufacturing, and creating inert atmospheres in laboratories.

- Argon: Widely used in welding, metal fabrication, and electronics manufacturing.

- Carbon Dioxide (CO2): Key in beverage carbonation, food freezing, and pH control in water treatment.

How to Choose the Right Microbulk System

When selecting a microbulk system, consider the following factors:

- Gas Usage: Understand the volume and frequency of gas use in your operations.

- Space Availability: Determine the available space for installing a microbulk tank.

- Safety Requirements: Ensure the system meets all safety standards and regulations.

- Supplier Support: Choose a supplier who offers reliable delivery and maintenance services.

Safety Considerations for Microbulk Gas Systems

Safety is paramount when dealing with any industrial gases. Here are key safety tips for microbulk systems:

- Regular Inspections: Conduct routine checks on the storage tank, vaporizer, and control systems to ensure they are functioning correctly.

- Proper Training: Ensure that all personnel handling the microbulk system are properly trained in safety protocols.

- Emergency Procedures: Have a clear emergency plan in place for gas leaks or other incidents.

- Ventilation: Ensure the storage area is well-ventilated to prevent the buildup of any potentially hazardous gases.

- Compliance with Regulations: Follow all relevant local and international safety standards and regulations.

Maintaining a Microbulk Gas System

To keep your microbulk gas system running efficiently:

- Monitor Gas Levels: Use the control panel to keep track of gas levels and arrange refills before they run low.

- Schedule Regular Maintenance: Regular servicing by the supplier can prevent system failures and ensure optimal performance.

- Check for Leaks: Regularly inspect all connections and valves for any signs of leaks, which could lead to safety hazards and gas loss.

- Calibration: Ensure that all pressure regulators and safety devices are regularly calibrated to maintain accuracy.

Environmental Impact of Microbulk Gases

Microbulk gas systems offer several environmental benefits:

- Reduced Transportation Emissions: Fewer deliveries are needed compared to high-pressure cylinders, leading to lower carbon emissions.

- Less Waste: The reusable nature of microbulk tanks means less waste compared to disposable cylinders.

- Efficient Gas Usage: Continuous supply minimizes gas wastage, improving overall efficiency.

Innovations in Microbulk Gas Technology

The field of microbulk gases is continuously evolving with innovations aimed at improving efficiency and safety:

- Smart Monitoring Systems: IoT-enabled systems allow for real-time monitoring of gas levels and predictive maintenance.

- Compact Designs: Newer microbulk systems are designed to be more space-efficient while maintaining the same capacity.

- Automated Refill Scheduling: Automated systems that alert suppliers when a refill is needed, ensuring continuous supply without manual intervention.

Conclusion

Microbulk gases represent a significant advancement in gas storage and delivery, offering numerous benefits over traditional high-pressure cylinders. From healthcare to manufacturing, these systems provide a continuous, reliable, and cost-effective gas supply while enhancing safety and environmental sustainability. By understanding the workings, applications, and maintenance of microbulk gas systems, businesses can optimize their operations and reduce costs while ensuring safety and compliance.

For over 80 years, Metro Welding Supply Corp has been the trusted partner for businesses across Southeast Michigan, delivering high-quality welding supplies, specialty gases, and exceptional customer service. Whether you’re in construction, manufacturing, or healthcare, we have the products and expertise to meet your needs. Our team is committed to providing reliable solutions that keep your operations running smoothly. Contact us today at 313-834-1660 or via email at sales@metrowelding.com to learn how we can support your business with the best in welding supplies and specialty gases.

FAQ's

What industries benefit most from microbulk gases?

Industries such as healthcare, food and beverage, manufacturing, and laboratories benefit greatly from microbulk gases due to their continuous supply and safety features.

How do microbulk systems compare to high-pressure cylinders?

Microbulk systems offer a more continuous supply, improved safety, and cost-efficiency compared to high-pressure cylinders, which require frequent handling.

Can microbulk gases be used in small businesses?

Yes, microbulk systems can be scaled to meet the needs of small businesses, providing a reliable gas supply without the space demands of bulk storage.

What gases can be stored in a microbulk system?

Common gases stored in microbulk systems include oxygen, nitrogen, argon, and carbon dioxide.

How often should microbulk systems be maintained?

Regular maintenance should be scheduled according to manufacturer guidelines, typically involving monthly inspections and annual servicing.

Ready to work with Metro Welding Supply Corp.?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 313-834-1660